difference between ch and cs cone crusher

Sandvik Cone Crushers - SRP

Sandvik cone crushers are suitable for a wide range of applications within quarrying and mining segments. End products for quarries include aggregates for concrete, asphalt and railway ballast. Our CS and CH cone crusher series combine extremely high

[خذ المزيد]

Cone crusher basics in 4 minutes

The Sandvik CH cone crusher can be calibrated to achieve specific results, maximize productivity and minimize wear, but any calculation will be undermined without a solid

[خذ المزيد]

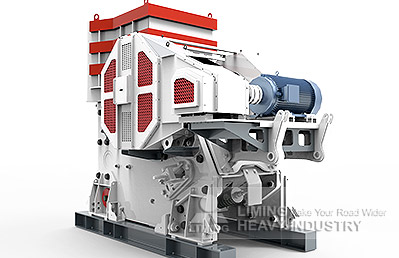

DESIGNED TO WORK SMART DELIVERED TO WORK HARD

These crushers offer optimal crushing for quarries of all sizes and mines. They’re smart too. Each new crusher has a connection to Sandvik cloud portal and ASRi 2.0 for

[خذ المزيد]

CONE CRUSHER CH SERIES CH440 - Sandvik Mining and Rock

ROCK PROCESSING GUIDE 2013. Cone Crushers CH series. Specification and Application range.

[خذ المزيد]

A Detailed Overview of Cone Crushers and What You

2020年6月3日 We will be exploring in more detail the following: Cone Crusher Manufacturers. How Does a Cone Crusher Work? Cone

[خذ المزيد]

SANDVIK CH870 CONE CRUSHER - Sandvik Mining and Rock

high-capacity cone crusher designed for your mine’s specific requirements. Each crusher has a hydraulically supported main shaft which is supported at both ends. With a robust

[خذ المزيد]

Sandvik CH440 Cone Crusher With A Robust Crusher Design - SRP

The versatile Sandvik SA1854 four deck circular motion screen and advanced Sandvik CH440 hydrocone crusher deliver a powerful blend of productivity and efficiency. The

[خذ المزيد]

CONE CRUSHER CS SERIES CS430

CONE CRUSHER CS SERIES CS430 ROCK PROCESSING GUIDE 2013 Chapter E Cone Crusher CS series Page 6 Specification and ... Nominal capacities MTPH for cone

[خذ المزيد]

4 Types of Cone Crushers: What Are They and How to

2023年4月28日 Learn about the application, advantages, and disadvantages of 4 types of cone crushers, and choose the right cone crusher. Here is a buying guide for cone crushers. Home

[خذ المزيد]

Cone Crushers (Parts of a Cone Crusher) Explained

Online Course . Article. Crushing. ‘Comminution’ is the term used to define the process that reduces materials (especially mined ore). It is the action of reducing a material to minute fragments or particles. The process is

[خذ المزيد]

4 Types of Cone Crushers: What Are They and How to

2023年4月28日 However, a cone crusher can also perform primary crushing if the feed size is small enough. Ftmmachinery engineer team makes a description and comparison between the 4 types of cone crushers, to help you choose

[خذ المزيد]

Gyratory Crusher vs. Cone Crusher: What's the

2023年2月23日 When it comes to crushing equipment in the mining industry, two popular options are gyratory crushers and cone crushers. While both types of crushers are designed to crush rock and other materials, there are significant

[خذ المزيد]

Cone Crusher - an overview ScienceDirect Topics

The cone crusher is a modified gyratory crusher, and accordingly many of the same terms including gape, set, and throw, apply. The essential difference is that the shorter spindle of the cone crusher is not suspended, as in the gyratory, but is supported in a curved, universal bearing below the gyratory head or cone (Figure 6.8).Major suppliers of cone crushers include Metso

[خذ المزيد]

Gyratory Crusher Cone Crusher Mantle Differences - 911

2015年7月25日 Difference between jaw crusher and gyratory crusher. Any of you that are at all familiar with the Gyratory crushers and Cone Crushers that the former are used as Primary crushers will probably note many similarities between the types. Each use a cone shaped crushing surface, and the same principal in the eccentric is employed to develop the crushing

[خذ المزيد]

Crusher Close Side Settings - 911 Metallurgist

2016年1月17日 The actual minimum safe closed side setting of a crusher will vary somewhat, for any given crushing machine, depending upon the character of the material, the amount of fines in the feed, and whether the crusher is being operated under choke-feed or regulated feed conditions. It is possible, when all conditions are favourable, to operate gyratory crushers, ...

[خذ المزيد]

Jaw Crusher VS Cone Crusher Which Is The Better Crusher

The common cone crushers on the market are divided into: Single Cylinder Cone Crusher, Multi Cylinder Cone Crusher, Hydraulic Cone Crusher, Movable Cone Crusher. 2. Adapt To Different Material. Jaw crusher can deal with the materials with high moisture content and high viscosity without blocking.

[خذ المزيد]

CONE CRUSHER CS SERIES CS430

CONE CRUSHER CS SERIES CS430 ROCK PROCESSING GUIDE 2013 Chapter E Cone Crusher CS series Page 6 Specification and ... Nominal capacities MTPH for cone crusher CS420 ECChamber C CSS 120-135 100-115 GG 125 105 SHNominal capacities MTPH 190 165 Max feed size (mm) ML 240 200 Max motor power (kW) 90 90

[خذ المزيد]

Jaw Crusher VS Cone Crusher Advantages and Disadvantages

There are five differences from jaw crusher vs cone crusher. Crushing Principle. Cone rock crusher and Jaw stone crusher are a laminated crushing principle. Which is commonly known as the impact crushing principle The nature of crushing doesn’t change too much, although the actuator of crushing use of different structure.

[خذ المزيد]

What is the difference between Impact Crusher and Cone Crusher?

Jaw Crusher VS Cone Crusher: 9 Key Differences. Jaw crusher and cone crusher have similar crushing principle, but different in many ways. In this article, we mainly talk about 9 key differences to help you choose the right crusher.

[خذ المزيد]

Sandvik CH440 Cone Crusher With A Robust Crusher Design - SRP

We have equipped this unit with the Sandvik CH440 cone crusher and a three deck 6' x 20' heavy duty screen with a high G force, to ensure outstanding efficiency, high productivity and reliability. UK373 Mobile unit UH373 The UH373 is an open circuit crushing unit fully assembled on a single triple axle trailer frame.

[خذ المزيد]

difference between mining cs and ch ne crusher - MC World.INC

difference between cs and ch cone crusher. difference between cs and ch cone crusher Related Information gold cleaning machines in shanghai china; cost of robo sand plant cost in india; jaw crusher in india mining Cone Crushers: The Suppliers' Perspective EMJ Jun 16, 2011 The company's CS and CH series of cone crushers have a wide field

[خذ المزيد]

difference between ch and cs cone crusher

CS series cone crushers (2ft, 3ft, 4 1/4ft, 5 1/2 feet standard and short head cone crusher) with capacity 50-400, 500-1300tph are used for quarry, mining,

[خذ المزيد]

Sandvik CS440 Cone Crusher With A Constant Intake Opening - SRP

Sandvik US440E mobile cone crusher is a highly efficient electrically powered, track-mounted complete process machine with a cone crusher and screen onboard. It has been designed to meet the demands of quarry operators, construction companies, mining companies or contractors working with highly abrasive materials, and it is the ideal

[خذ المزيد]

Should I Choose an Impact Rock Crusher or Cone Crusher?

Cone crushers, a type of compression crusher, have less versatility than a horizontal impact crusher, but a great capability to guarantee a finished product size. If set at 2, typically 80% of the final product will meet the 2 target which is not something that can be replicated by jaw crushers or impact crushers.

[خذ المزيد]

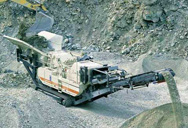

Types of Crushers: What You Need to Know Machinery Partner

ARK 2416 jaw crusher in action Gyratory crushers. Run of mine material is transferred into a gyratory crusher’s upper-level hopper. The walls of the gyratory crusher’s hopper are lined with “V-shaped” pieces, the mantle and the concave, like a

[خذ المزيد]

Types of Crushers Explained: Everything You Need to Know - JXSC

A short-head cone crusher has a short crushing chamber and it is designed for the production of finer output sizes, generally between 6 mm and 25 mm. A fine cone crusher, also known as a tertiary cone crusher, is used for the production of They are manufactured to produce very fine output sizes, mostly below 6 mm.

[خذ المزيد]

Cone Crusher Liners: How to Select and When to Change

Cone Crushers were developed more than a century ago to provide secondary, tertiary and even quaternary material reduction.. Like other compression crushers, Cone Crushers feature a crushing chamber or cavity where the rock is crushed to a smaller size.The crushing chamber in a Cone Crusher is the space created between the mantle (the

[خذ المزيد]

CH895i - SRP

Several different crushing chambers are available for the CH895i as standard. ... Sandvik CH895i is a technologically advanced, high-capacity cone crusher designed for crushing applications in mines or large sized quarries. It has a hydraulically supported main shaft which is supported at both ends. With the Sandvik CH895i, ...

[خذ المزيد]- ماكينات صناعة الأسفلت الصغيرة للبيع

- في فرنسا صنع آلة

- الهند خلع الملابس طحن الحجر الرملي

- دارات الكشف عن الذهب

- تصميم قدرة المطرقة محطم

- الفولاذ المقاوم للصدأ الفك Ep

- الكوارتز والرمل السيليكا تصنيع تركيا

- المطرقة مطحنة الرسم والعمل البناء

- خام طحن الكرة مطحنة الكرة طحن الكرة مطحنة الكرة آلة السعر

- طاحونة العمود المرفقي 文件

- رقيقة مصنع آلة الطوب ملموسة

- معمل كسارة مسحوق الرخام في السعودية

- صيانة الفك محطم قائمة مرجعية

- المستخدمين كسارة الصين جنوب أفريقيا

- أفضل الموردين للكسارات الحجرية المتنقلة

- رخيصة كسارات خام الكروم المطاحن

- مصنع غربلة الذهبقرب لي

- سنگ شکن های موبایل برای فروش uae

- دستگاه برش سنگ معدن

- تولید کننده تجهیزات خرد کردن سرباره

- كسارة متنقلة في الهندية

- كسارة الحجر perusahaan في اندونيسيا

- صغير مزود الحجر الجيري محطم في جنوب africac

- غسل الرمال المصنعين

- سعر كسارة جسر شنغهاي

- كسارة الحجر آلة كاملة للبيع آلة كسارة الحجر

- دستگاه سنگ شکن کره جنوبی فقط

- إنتاج الرمل خط ملموسة

- مصنع التعويم للفلدسبار

- ضربه آفریقای جنوبی سنگ شکن

© Copyright - PETER&X محطم